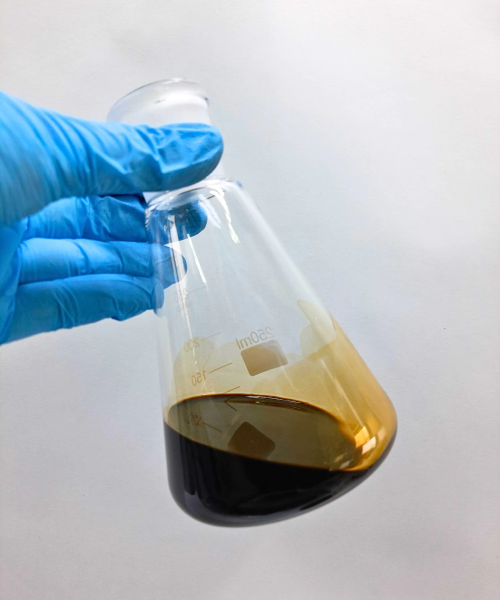

Rubber Pyrolysis Oil

Pyrolysis oil is the end product of waste tyre and plastic pyrolysis, the oil is wide used as industrial fuel to substitute furnace oil or industrial diesel. Typical industrial applications of pyrolysis oil as a fuel, the fuel oil is mainly used in Machine do not require high quality fuel oil.

The pyrolysis oil is extracted from waste tyre or waste plastic by our pyrolysis plant, the pyrolysis plant is a machine converts waste tyre to oil. During the process of converting waste tyre/plastic to fuel oil there will be no pollution and solid waste. The end product of pyrolysis plant is fuel oil, carbon black, and oil gas.The raw material such as waste plastic/tyre will be heated in reactor, then the waste tyre/plastic will vaporize, the vaporize oil gas will go into condenser and condensed into liquid fuel oil.the fuel oil is a good energy.The dedusting system will deal with the waste perfectly, just little energy is required to heat the energy, the oil gas which cannot be condensed will be recycled back to heat reactor. Thus will save much energy.

The pyrolysis oil is mainly fuel oil used in heavy industry such as construction heating, steel factory, cement factory, boiler factory; hotel heating etc, the oil is closed to NO.2 diesel. By direct combustion in a boiler or furnace pyrolysis oil can be used to produce heat. This is the most simple and straight forward application combustion of pyrolysis oil in heavy industry is available. This application offers some companies the possibility to partly from natural gas, or heating oil to a renewable alternative fuel. pyrolysis oil is completive with the price of heating oil, more and more countries are using pyrolysis oil to replace natural gas. Pyrolysis oil has the potential to be available in large amounts and competitively priced. Once the plastic/ tyre oil refined it can be used many different ways. Such as truck, tractor, ship, diesel power generation and so on. The pyrolysis oil is mainly used in heavy industries for heating purpose as fuel, usually used in industry or machine which doesn’t require high stand oil like steel factory, cement factory, brick factory and glass factory etc. Especially steel factory and cement factory.

We got to know from customers’ feedback that one normal factory can consume 20-30T oil in one day. Most of our customers sold their oil to steel factories. In some places like Egypt, they have many cement factories. So the oil is usually used in cement factory. Following is picture about application of pyrolysis oil.

Rubber Pyrolysis Oil

Specification

The table shows the specifications of Rubber Pyrolysis Oil:

PROPERTY | METHOD | RESULT | UNITS |

Flash Point by PMCC | ASTM D93-12 (Procedure B) | <40 | °C |

Density at 15°C | ASTM D4052-11 | 0.9146 | g/cm3 |

Total Sulphur Content | ASTM D4294-10 | 0.650 | % (m/m) |

Ash Content | ASTM D482-07 | 0.002 | % (m/m) |

Carbon Residue – Micro Method | ASTM D4530-11 | 0.38 | % (m/m) |

Kinematic Viscosity at 40°C | ASTM D445-12 | 3.561 | mm2/s |

Water Content | ASTM D95-05 (2010) | 0.05 | % (V/V) |

Gross Calorific Value | ASTM D4868-00 (2010) | 44.32 | MJ/kg |

Net Calorific Value | ASTM D4868-00 (2010) | 41.74 | MJ/kg |

Acid Number (Infection end-point) | ASTM D664-11a (Method A) | 2.2 | Mg KOH/g |